Butyl tin maleate

Product name:

Dibutyl tin maleate, tributyl tin oxide, dibutyl tin crotonate, dibutyl tin maleate, dibutyl tin maleate , Dibutyl tin maleate, dibutyl tin anhydrous malate, dibutyl tin maleate, 2,2-dibutyl-1,3,2-dioxazepam-4,7-dione, loss Dibutyl tin malate water, dibutyl tin maleate oligomer, butyl tin maleate

Dibutyltin maleateDibutyltinmaleateDibutyltinmaleateButyltinmaleate CAS 78-04-6

[English name]

2,2-dibutyl-1,3,2-dioxastannepin-4,7-dione, cis-Butenedioic acid dibutyltin, DBTM, Dibulyltin maleate, DIBUTYL(MALEOYLDIOXY )TIN, DIBUTYLTIN MALEATE, Didutyltin maleate, DI-N-BUTYL-DIOXASTANNEPIN-4,7-DIONE, DI-N-BUTYL(MALEATE)TIN, DI-N-BUTYLTIN MALEATE, 1,3,2-Dioxastannepin-4, 7-dione,2,2-dibutyl-,2-dioxastannepin-4,7-dione,2,2-dibutyl-3,3,2-Dioxastannepin-4,7-dione,2,2-dibutyl-1, Advastabdbtm , Advastabt290, advastabt340, bt31, Dibutylstannylenemaleate, Irgastabdbtm, irgastabt150

| Dibutyltin maleate | Dibutyltin maleate | Dibutyltin maleate | Butyl tin maleate | CAS 78-04-6 |

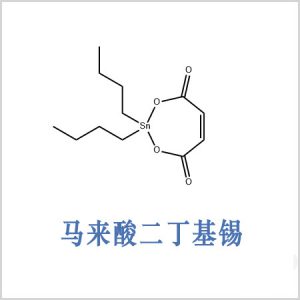

Molecular formula: C12H20O4Sn

Molecular weight: 346.98

CAS#: 78-04-6

Melting point: 110℃

Flash point: 204℃

Tin content: 33%-34%

Physical and chemical properties

[Appearance properties] White amorphous powder, hygroscopic and tear-inducing.

【Solubility】Insoluble in water, slightly soluble in benzene and toluene.

[melting point] 135-140 °C(lit.)

[Density] 1,318 g/cm3

[Refractive Index] 1.502

[Flash point] 204°C

Product traits:

White amorphous powder. Decompose by heating. Soluble in ethanol, benzene and organic esters, but insoluble in water. Toxic and irritating.

Product Application:

Used as heat stabilizer in PVC rigid transparent products

Polyvinyl chloride heat stabilizer, with excellent thermal stability, weather resistance and transparency. It is mainly used for PVC hard and transparent products. Condensation catalyst. Gasoline anti-explosive agent, the general dosage is: 0.5%-2%.

[Use 1]

Used as heat stabilizer in PVC rigid transparent products

[Use 2]

This product is a heat stabilizer for polyvinyl chloride. It has excellent heat resistance and transparency, no vulcanization pollution, and long-term heat resistance is particularly good. Prevent the product from turning yellow during high temperature processing. This product is especially suitable for hard transparent products, and its melting point is higher, which will not reduce the softening point and impact of hard products. The general dosage is 0.5-2%. It has a synergistic effect when used together with barium soap or cadmium soap, which can further improve the stability effect. When used together with dibutyltin laurate, it can further improve the transparency and heat resistance of the product. It can be reduced when used together with epoxy compounds. Its tear gas. This product lacks lubricity and poor processing performance; because of its volatility, it sometimes foams during processing; moreover, under the action of hydrogen chloride generated during heating, the product will translocate into fumarate, which is in phase with the resin. Decreased capacity, easy to spray frost. To overcome these shortcomings, many modified varieties have been developed.

[Use Three]

Condensation catalyst. Gasoline explosion-proof agent. The heat stabilizer of polyvinyl chloride (PVC) has excellent heat resistance and transparency, no vulcanization pollution, and particularly good long-term heat resistance, which can prevent the product from turning yellow during high temperature processing.

Package: Packed in cardboard drum, the packing specification is 25㎏/barrel.

Storage: Store in a ventilated and dry place.