Dimethyldineodecanoatetin

Overview:

Product name: Dimethyltin dioctanoate, CAS 68928-76-7, Dimethyldineodecanoatetin, Fomrez UL -28

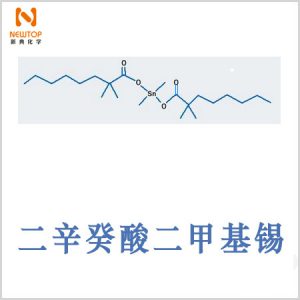

Dimethyltin dineodecanoate is an organic compound with the chemical formula C12H44O4Sn.

Product name: Dimethyltin dioctanoate 68928-76-7

Product code: DDDO

| Chinese name | Dimethyltin dineodecanoate | |||

| Foreign name | Dimethylbis[(1-oxoneodecyl)oxy]stannane | |||

| 分 Sub-style: | C12H44O4Sn | |||

| CAS No.: | 68928-76-7 | |||

| Project | Metrics | |||

| Appearance | clear viscous liquid | |||

| Chroma (Pt-Co number) | ≤50 | |||

| Refractive index(25°C) | 1,4630 – 1,4730 | |||

| Density(25°C) | 1,1230 – 1,1630 | |||

| tin content | 22,50% – 24,50% | |||

| Moisture | < 0.40% | |||

| chlorine content | < 0.20% | |||

| Dimethyltin dioctanoate | Dimethyldineodecanoatetin | CAS 68928-76-7 | Dimethyltin Dineodecanoate | |

English name: Dimethyldineodecanoatetin

CAS number: 68928-76-7

Molecular formula: C22H44O4SN

Production method:

It is made by dehydrochlorination of dichlorodimethyltin and neodecanoic acid.

Erxin Dimethyldineodecanoatetin CAS 68928-76-7 Dimethyldineodecanoatetin

Impact on the environment:

U.S. Occupational Safety Administration (OSHA) uses organotin environmental safety standards for all industries [8H TWA (8-hour average) is 0.1mg/m (in tin Calculate); The short-term exposure value is 0.2 mg/m];

Purpose:

Clarified viscous liquid

As a high-efficiency catalyst in the manufacture of polyurethane foam, coatings, adhesives and sealants. It is used as a hardening catalyst for bipartite polyurethane, polyester, nitrocellulose paint, ink and other coatings and warm-air hardening coatings, with good oxidation resistance; used for the production of polyurethane plastics, polyurethane coatings, silicone rubber catalysts, driers, etc. use.

Storage method:

Normal temperature, protected from light, ventilated and dry place, sealed and stored

Storage and transportation:

Store in an airtight container in a cool, dry place. The storage place must be locked, and the key must be handed over to the technical experts and their assistants for safekeeping. The storage place must be far away from oxidants and water sources.

General-purpose plastic and plastic-sprayed iron drums or glass containers are packaged and transported in accordance with general chemical management regulations.

Packaging:

Packaging: It is suitable to be stored in glass containers, plastic containers, and metal utensils resistant to corrosion by chlorine, and kept tightly sealed. Store in a cool, dry place, keep the container tightly closed, and avoid contact with oxides. Do not inhale dust and avoid contact with skin and mucous membranes. Smoking, eating and drinking are prohibited in the workplace. After work, take a shower and change clothes. Store contaminated clothes separately and use them after washing. Maintain good hygiene habits.