HDI trimer AsahiKasei TPA-90SB

Date:2023-11-21 Categories:Application

Type:

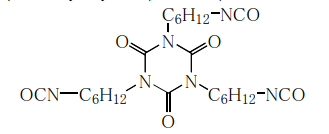

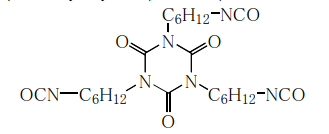

Aliphatic Polyisocyanate (HDI Trimer)

Features:

# High NCO content

# Lower viscosity

# Good coated film appearance

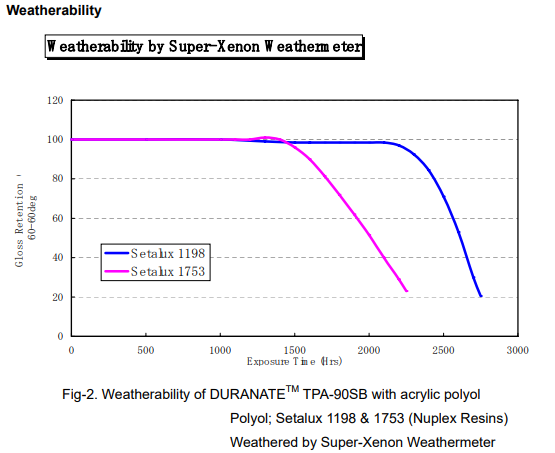

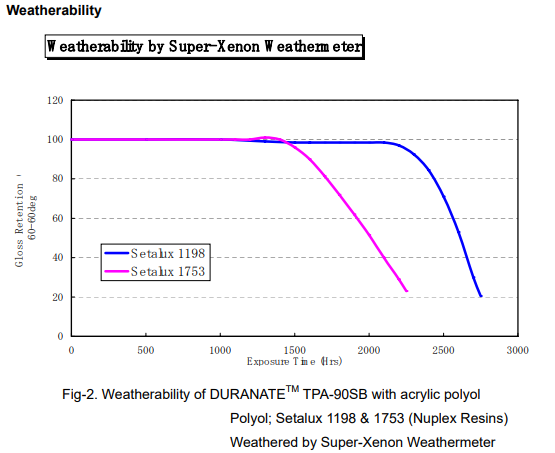

# Good weather resistance

# Low residual monomer

Applications:

# Two-component applications

# Plastic coatings

# Auto refinish coatings

# Automobile, motorcycle ; base coat and top coat

# Heavy duty coatings

Typical properties:

Appearance

|

Colorless to slightly yellowish clear liquid

|

Non-volatile

|

90 wt%

|

Solvent

|

Solvent naphtha (petroleum),light arom. / Butyl acetate=1/1

|

NCO content

|

20.9 wt%

|

Viscosity

|

310 mPa·s at 25℃

|

Color value

|

< 1 (Gardner)

|

NCO equivalent weight

|

Approx.201

|

Flash point

|

60℃

|

Density at 20℃

|

1.13

|

These values provide general information and are not part of the productspecifications.

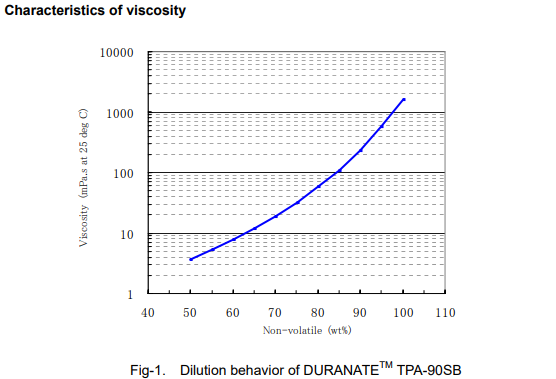

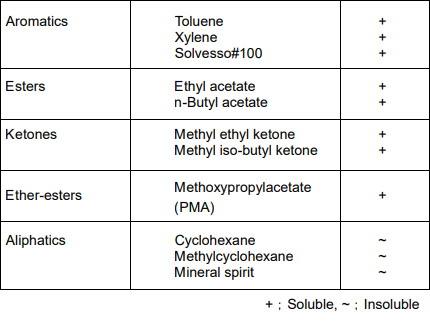

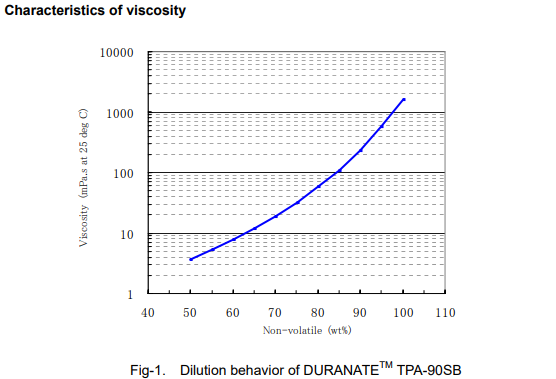

Stability/ thinnability:

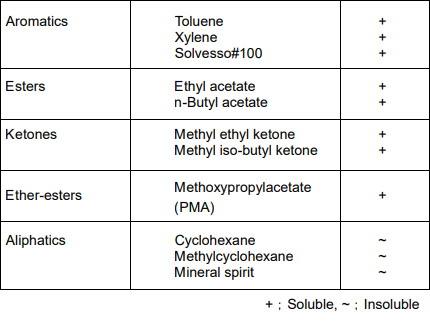

DURANATETM TPA-90SB can be thinned with esters, ketones and aromatic.hydrocarbons such as ethyl acetate, butyl acetate, methoxypropylacetate(PMA), methylethyl ketone, methyl-butyl ketone, cyclohexanone, toluene, xylene, Solvesso #100 andmixture thereof. Generally speaking, it has good compatibility with the solventmentioned. However, the solutions formed must be tested for their storage stability.Only PU grade solvents can be used (max. 0.05% water, absence of reactive groupssuch as hydroxyl or amines groups). Aliphatic hydrocarbons such as hexane.cyclohexane, methylcyclohexanes and mineral spirits, are unsuitable as solventsbecause of their poor solubility.

DURANATETM TPA-90SB should not be thinned to below a solid content of 40%.Prolonged storage of solution with lower solid content may result in turbidity andsedimentation.

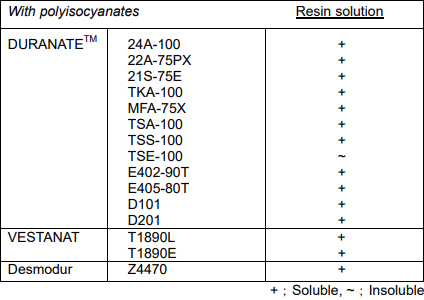

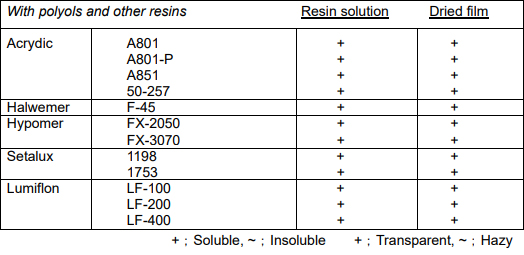

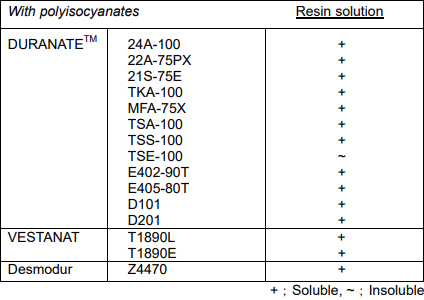

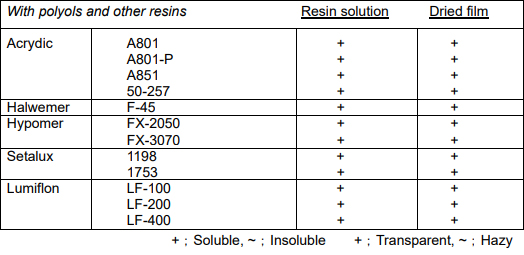

Compatibility:

Mixing ratio of DURANATETM TPA-90SB with polyols is based on NCO/OH equivalentratio of 1/1 .

Storage:

DURANATETM TPA-90SB is sensitive to moisture and should therefore always bestored in sealed containers.

Packaging:

200KG/drum Please fasten the packaging cover as soon as possible after original packaging to prevent the mixing of other substances such as moisture and other substances that may affect the performance of the product. Do not inhale dust, avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, shower and change clothes. Store contaminated clothes separately and reuse them after washing. Maintain good hygiene practices.